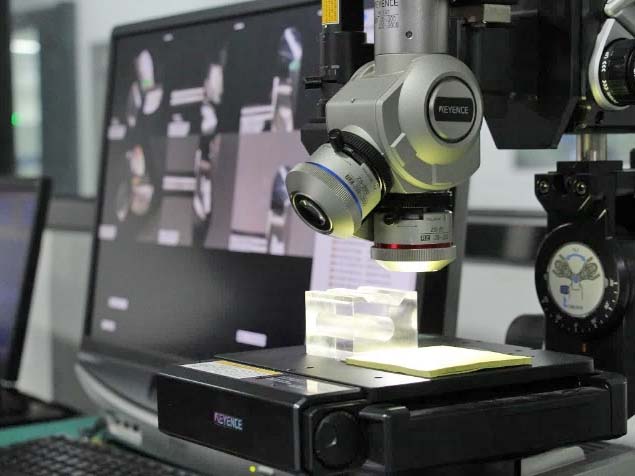

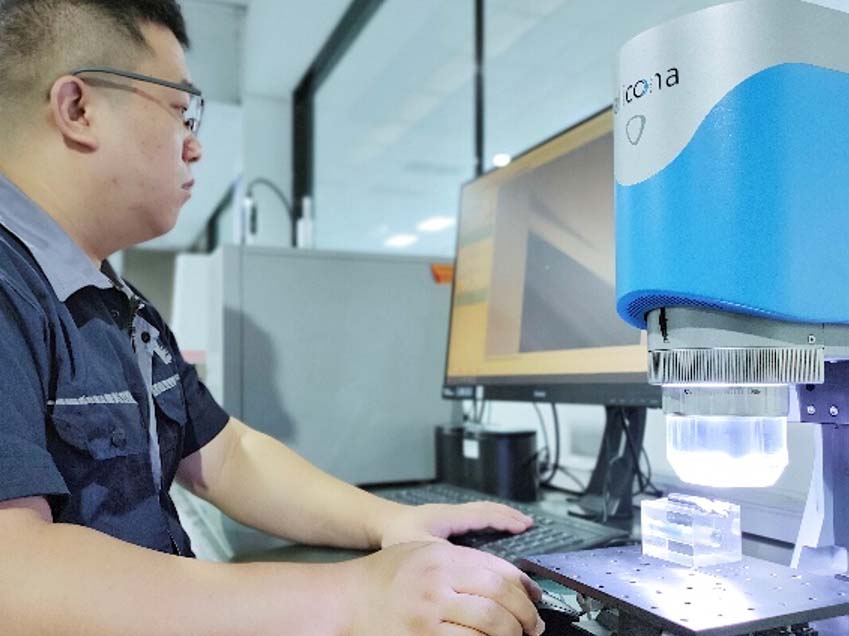

Based on the IS09001 quality assurance system as the standard, adhering to the belief of "zero defect in products and zero distance of service", there are also high-precision inspection equipment to meet customers' high-quality standard requirements.

Before each material is put into storage, it must pass the specified standards, and Haili's requirements for quality start from the source!

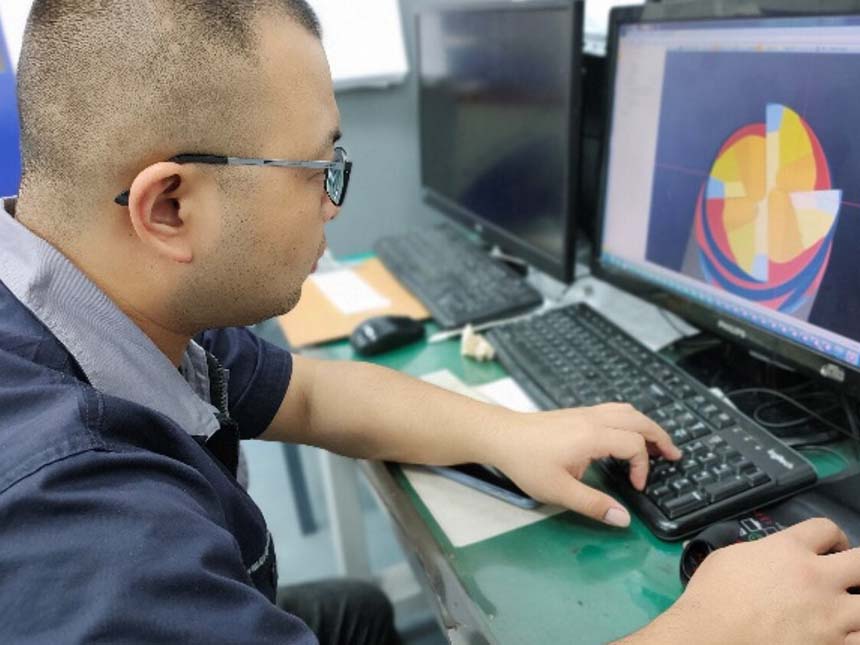

Senior professional engineering personnel, based on customer requirements and equipment characteristics, use reasonable and efficient processing procedures to ensure that production quality meets the required standards!

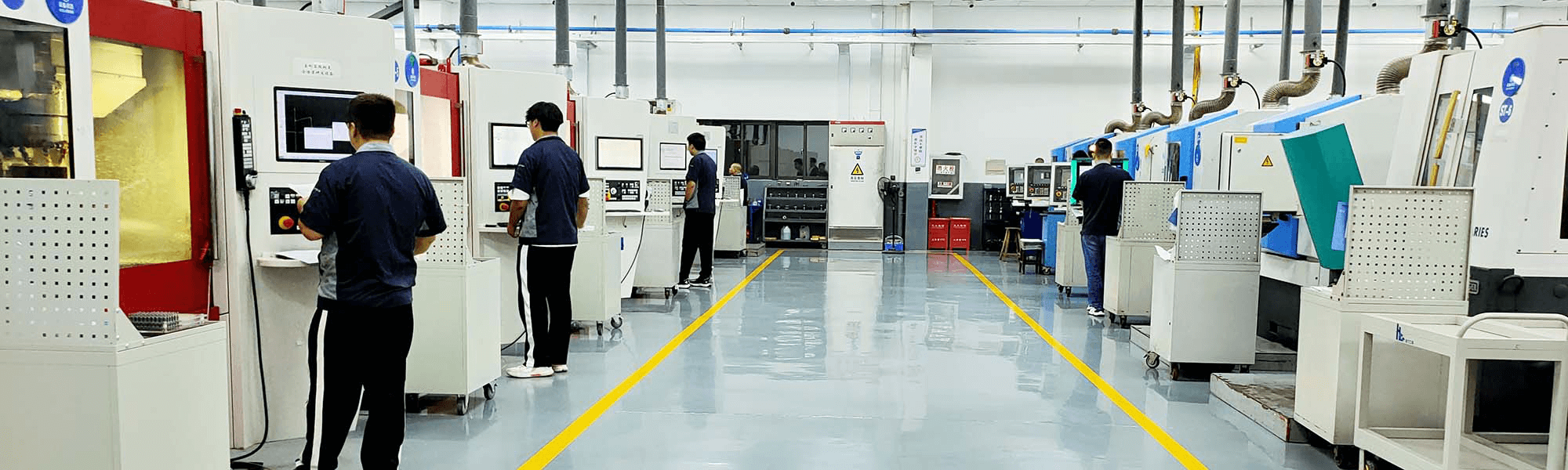

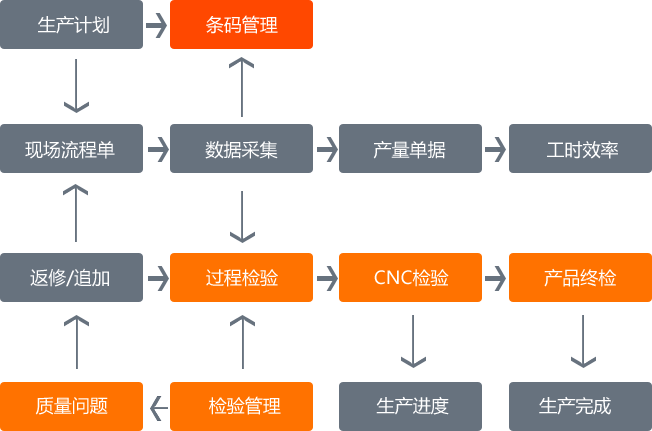

The transfer of each process is controlled by an intelligent production process management system to prevent the circulation of defective products and ensure the quality of each process output! Moreover, it ensures the quality of every cutting tool that leaves the factory!

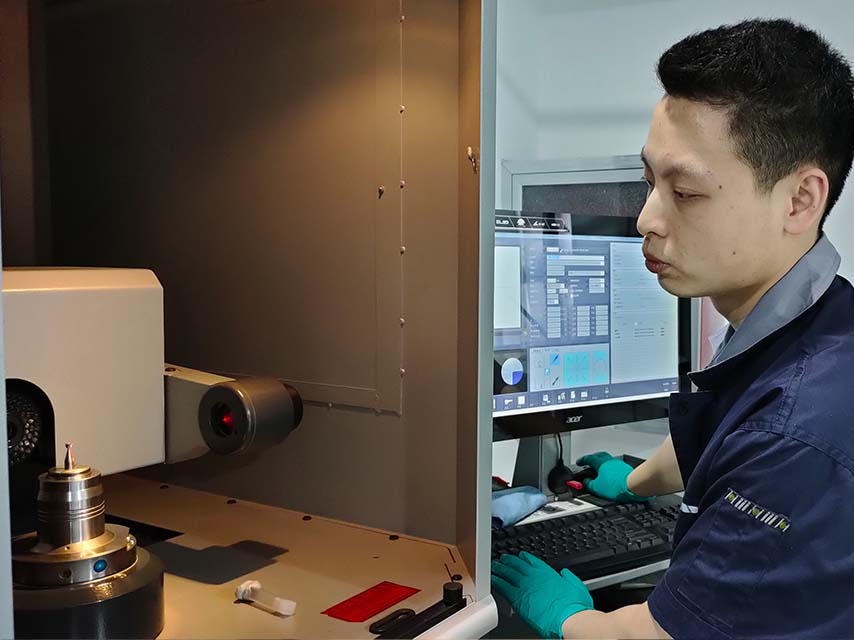

Haili has its own passivation process processing and testing capabilities to avoid quality risks caused by difficult outsourcing management! Ensure that each tool meets the customer's requirements for tool life!

For each quality situation, according to the principle of overall quality management, establish standards for identifying, solving, implementing standards, and preventing recurrence. Regularly train and cultivate correct quality concepts!